TENRON Strong by Nature

Tenron is nature’s strongest mineral material.

Tenron is a disruptive material made out of an aggregation of widely available minerals extracted in Western Europe.

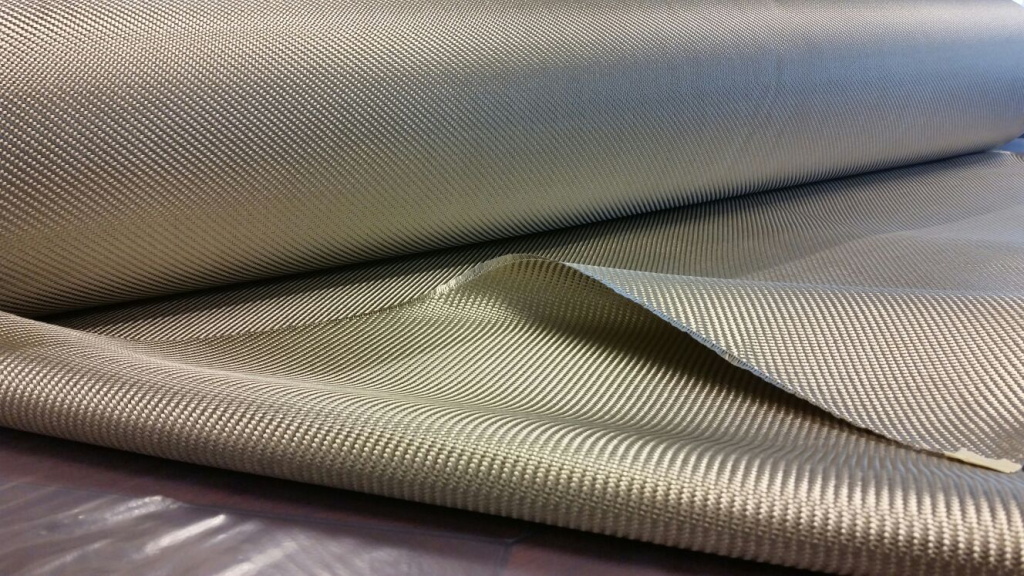

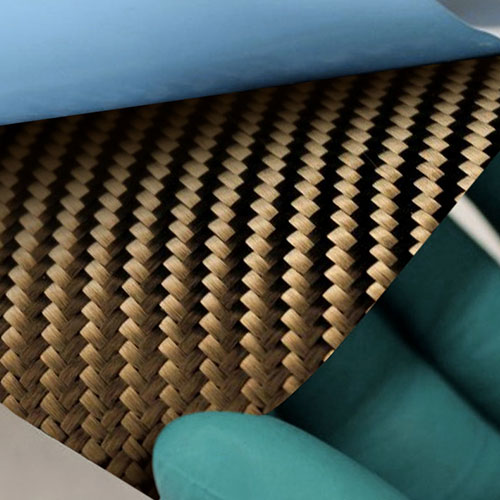

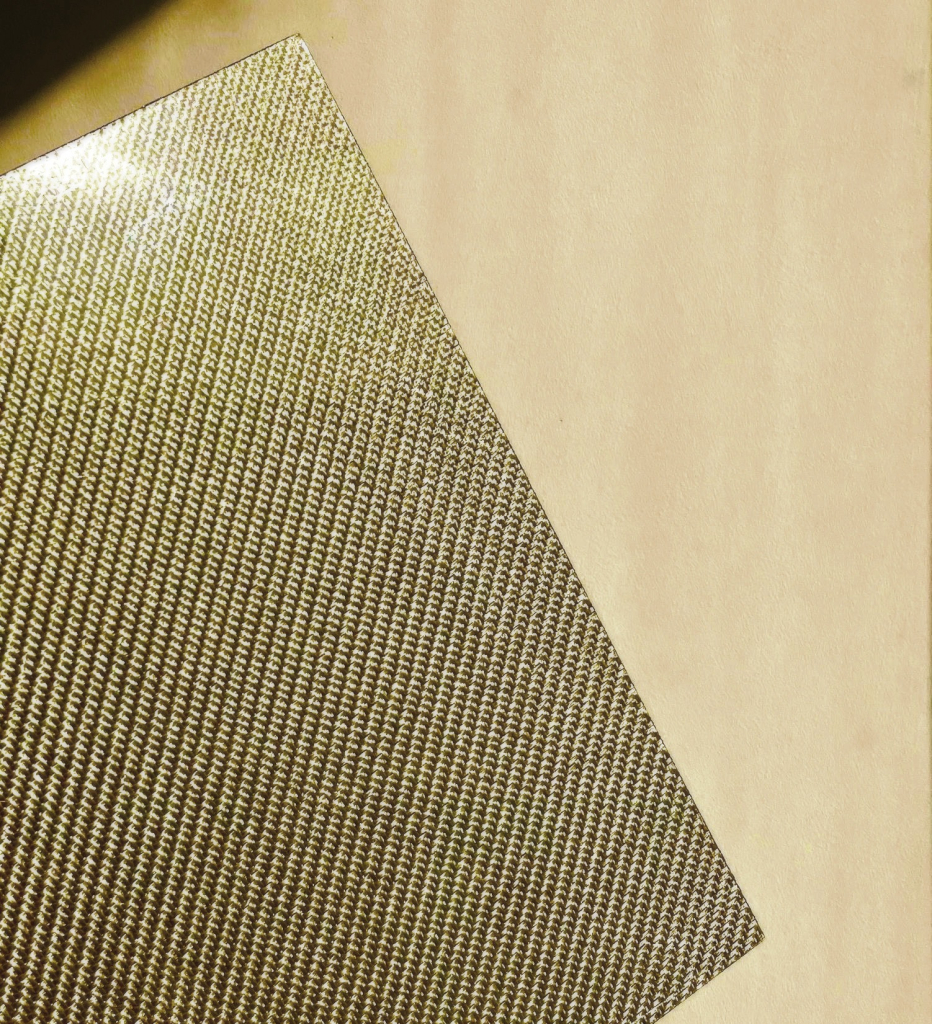

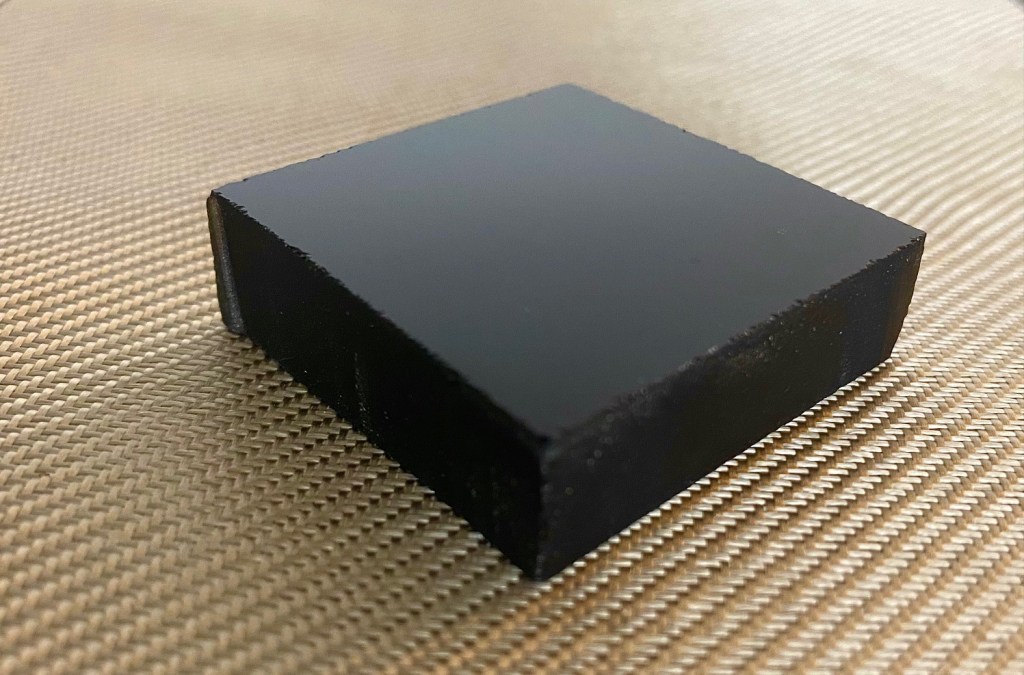

Tenron is available in different formats: Tenron fibres and its downstream products, Tenron textiles, Tenron felts, Tenron pre-impregnated rovings or textiles, Tenron composites and Tenron hybrids. Tenron fibre is the world’s highest performing mineral fibre and is aerospace grade.

Tenron is produced by Tenron, a premier European manufacturer located in Belgium.

Tenron belongs to the category of “New Materials” alongside esteemed materials like carbon or aramid. The New Materials revolution advances the materials and tools developed during the Industrial Revolution of the 20th century and the Stone Age, the Bronze Age and the Iron Age before that. New Materials combine various sophisticated technologies. The market for such materials over the coming years is estimated at more than EUR 150 billion.

Tenron requires significantly less energy (kWh) to produce compared to existing high-performance materials like carbon and aramid, and it can be recycled back to its original properties. Tenron has an exceptional durability (long lifetime). (see LCA)

Tenron is a game changer. It will play a key role in the circular economy and in the clean energy transition.